Remark: This document was translated using generative AI technology.

Hello. I'm Ogata from the Converging Technologies Laboratory. We are developing "Supply Chain Digital Rehearsal" technology to support companies' mid-to-long-term strategic decision-making. I'd like to introduce the features of this technology and our joint verification with a major food company targeting their product supply chain.

Fujitsu Develops "Supply Chain Digital Rehearsal" Technology

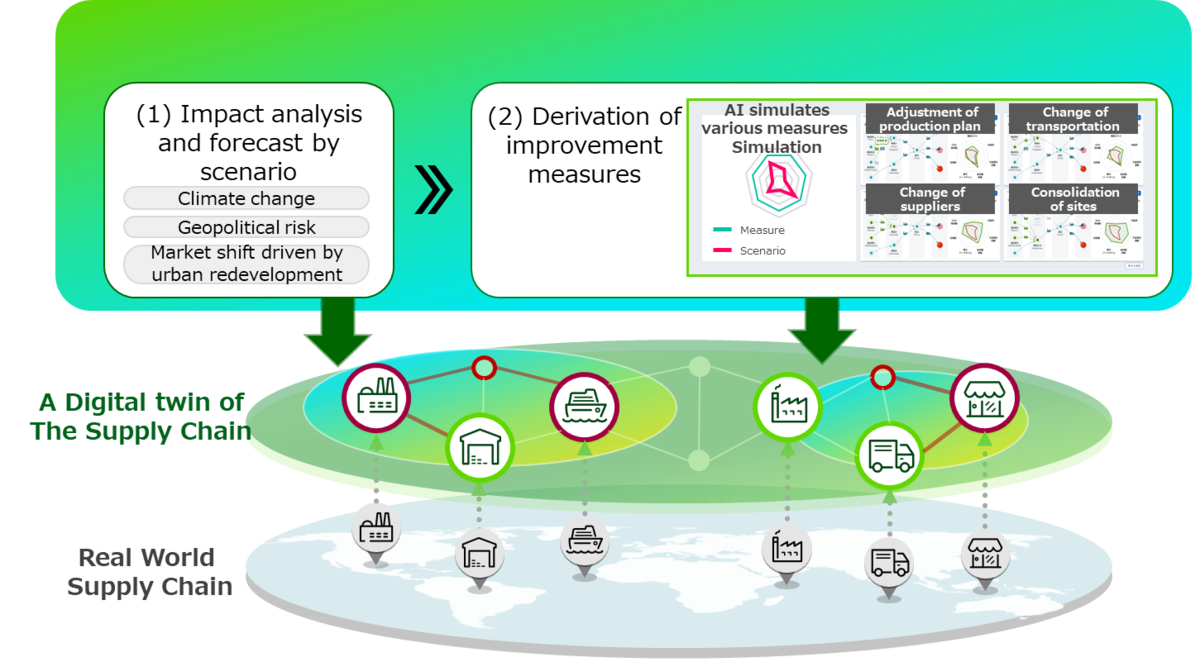

In recent years, the environment surrounding corporate supply chains has become increasingly uncertain, driven by climate change, geopolitical risks, logistics disruptions, soaring material costs, and shifts in consumer demographics within commercial districts due to urban development. These events have the potential to severely impact corporate procurement, logistics, manufacturing, and sales systems, making it difficult to respond using conventional, standardized risk management approaches. In light of this situation, Fujitsu has developed "Supply Chain Digital Rehearsal" technology to support strategic decision-making from a medium- to long-term perspective (Figure 1).

In Supply Chain Digital Rehearsal, after constructing a digital twin that maps the structure of the real world supply chain into a digital space, it supports decision-making to optimize the supply chain structure as follows.

When uncertainty scenarios —such as where and how uncertainty events like "climate change," "geopolitical risks," or "urban development in commercial areas" might occur— are applied to the supply chain on the digital twin, (1) the system automatically analyzes where and how these uncertainty scenarios will impact the supply chain. (2) Then it automatically proposes multiple improvement measures, including supply chain structural changes such as hub consolidation or supplier switching, to minimize the impact of the analyzed and predicted effects. The proposed measures are automatically evaluated across multiple perspectives, such as cost, delivery time, inventory levels, and environmental impact, making it easy to narrow down appropriate measures and facilitate decision-making. This enables companies to minimize the impact through preemptive countermeasures when an uncertainty scenario actually occurs, or to respond swiftly by implementing prepared measures (Figure 2).

We are confirming that the impacts and measures generated by this technology for the supply chain structure are not only equivalent to expert analysis results but also present high precision and quality across multiple perspectives, such as cost and delivery time.

Details of Development Technology

Let me introduce the technologies that make up "Supply Chain Digital Rehearsal" technology.

(1) Analysis and Forecasting Technologies for Impacts in Uncertainty Scenarios

Risk Scenario Analysis Technology : This technology analyze "risk scenarios"—where and how uncertain scenarios impact supply chains—based on public information and company-specific data. This process comprehensively and automatically extracts the causal chain from the occurrence of an uncertain scenario to its final impact. Here, the events occurring between the uncertain scenario and the final impact are termed "intermediate factors." Identifying these intermediate factors helps understand why and how uncertain scenarios cause the final impact.

Scenario Forecasting Technology : This technology forecasts the medium- to long-term time-series changes in quantitative indicators whose values fluctuate under the influence of multiple factors such as supply and demand and price. For example, container ship ocean freight rates fluctuate due to the impact of multiple factors including fuel prices, cargo volume, and available tonnage. It automatically generates a freight rate forecasting model based on the causal relationship between each factor and freight rates, along with change scenarios for each factor. For each change scenario, it forecasts the time-series changes in ocean freight rates along with their fluctuation ranges. This enables the identification of potential landing points for the targeted quantitative indicator based on signs of change in each factor, facilitating the consideration of countermeasures.

Furthermore, we are developing Stress estimation technology utilizing digital twins. This technology estimates the degree of performance degradation based on impact models under uncertainty scenarios and past data.[*1]。

(2) Technology for Derivation Improvement Measures

Measures Exploration Technology: This technology comprehensively explores measures—such as expanding supplier bases, changing logistics methods, adjusting inventory levels, and consolidating or closing facilities—to minimize the impact of uncertain scenarios on the supply chain.

Consensus Building Support Technology: This technology assists in narrowing down appropriate improvement measures from the vast pool of candidates explored by the Measure Exploration Technology, based on multiple criteria such as cost, delivery time, inventory levels, and environmental impact. This facilitates consensus-building among stakeholders with differing values, such as personnel from different departments, during the measure selection process.

Joint Verification with a Client Company

We conducted a joint verification of development technologies with a major food company. This joint verification targeted a product supply chain, simulating the closure of the Suez Canal due to conflicts as an uncertainty scenario. We analyzed the impact on maritime transportation for raw material procurement, predicted the time-series changes in medium-to long-term quantitative indicators, and attempted to derive improvement measures to minimize the impact.

Comprehensive analysis of impacts from the uncertainty scenario

In addition to the increase in shipping days due to the Suez Canal detour, we were able to automatically extract the following chain of compounding effects and the resulting decrease in raw material inventory:

- Disruption at shipping sites and heightened navigation risks

- Disruption to loading and operational schedules and changes in shipping demand

Thus, we confirmed that comprehensive analysis is possible, covering not only direct impacts like increased shipping days but also intermediate factors that cause indirect effects.

Forecasting medium- to long-term time-series changes under the uncertainty scenario

We forecasted the medium-to long-term time-series changes in ocean freight rates for each change scenario that altered the pattern of increased cargo volume resulting from the Suez Canal closure. Comparing the forecast results with past cases confirmed that the model correctly captured the tendency for ocean freight rates to surge sharply, validating its technical feasibility.

Deriving multiple improvement measures to minimize impact

In addition to achieving results comparable to those of expert-designed measures, we were able to derive appropriate alternative routes and other measures from multiple perspectives, including cost. This earned high praise from major food companies regarding the accuracy of our technology derivation.

Regarding the Future

Moving forward, we will advance verification and technological enhancement to expand into diverse industries, including manufacturing. This technology will support companies in formulating supply chain strategies through comprehensive impact analysis and multi-perspective improvement planning, contributing to strengthened resilience and sustainable business operations. Stay tuned for future developments in Supply Chain - Digital Rehearsal!

Links

Dynamic Supply Chain Management

https://global.fujitsu/ja-jp/offering/digital-supply-chain-management

Fujitsu develops multi-AI agent collaboration technology to optimize supply chains, launches joint trials

https://en-documents.research.global.fujitsu.com/resilient-supply-chain/